Blog

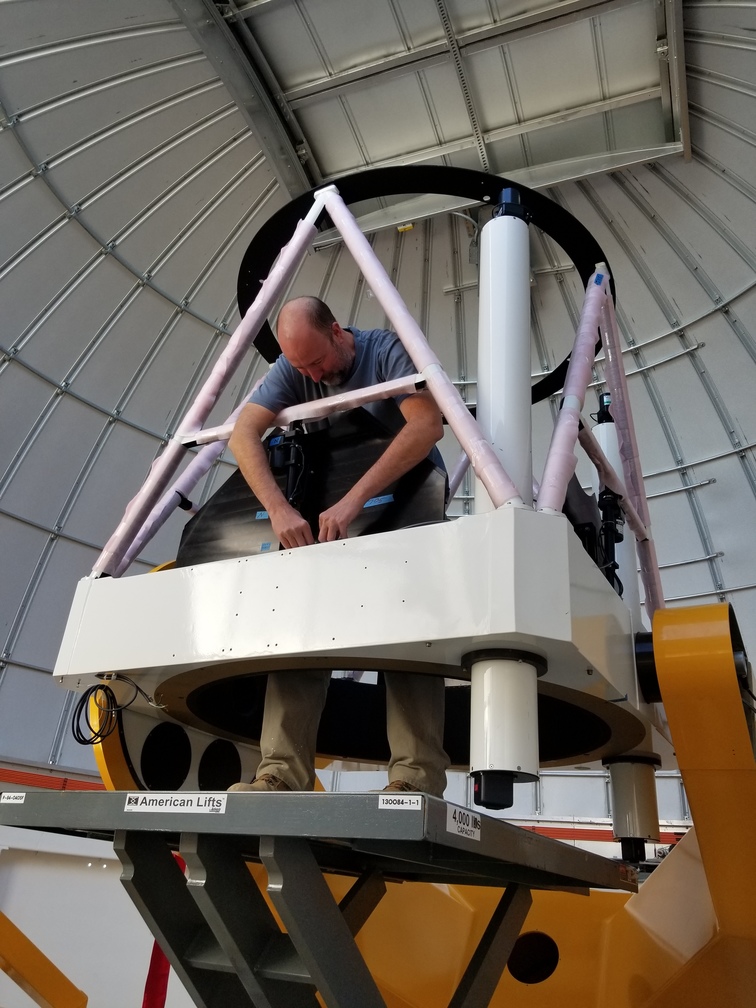

Today we did a dry run of the primary mirror cell installation. With no mirror installed, we brought the mirror cell up to the observing floor and installed it on the bottom of the telescope. We then removed it and lowered it back down to the ground floor. The test was successful, and it was a useful exercise since we now have a better idea of what we will be doing when we do the installation for real.Here are a couple photos.Mirror cell ready for lifting.

On its way up.

Up through the hatch.

Gantry crane rolled over to the lift table.

Mirror cell set down on the lift table.

Lifted up to...

2017-09-18

#Telescopes

Today we worked on getting the telescope and mirror cell at Site #2 ready for installation of the mirrors. We also got the focus system powered up and working with the TCS. We got the trusses, focus ring, and mirror doors installed, and we also got the spreader bar and spacers ready for the primary mirror cell.

Tomorrow we plan to test the mirror doors and adjust the limit switches, and to get the focus housing cables installed on the tube assembly (currently the cables are connected directly to the focus housing on the stand on the observing floor). We also need to drill out the holes on the...

2017-09-17

#Telescopes

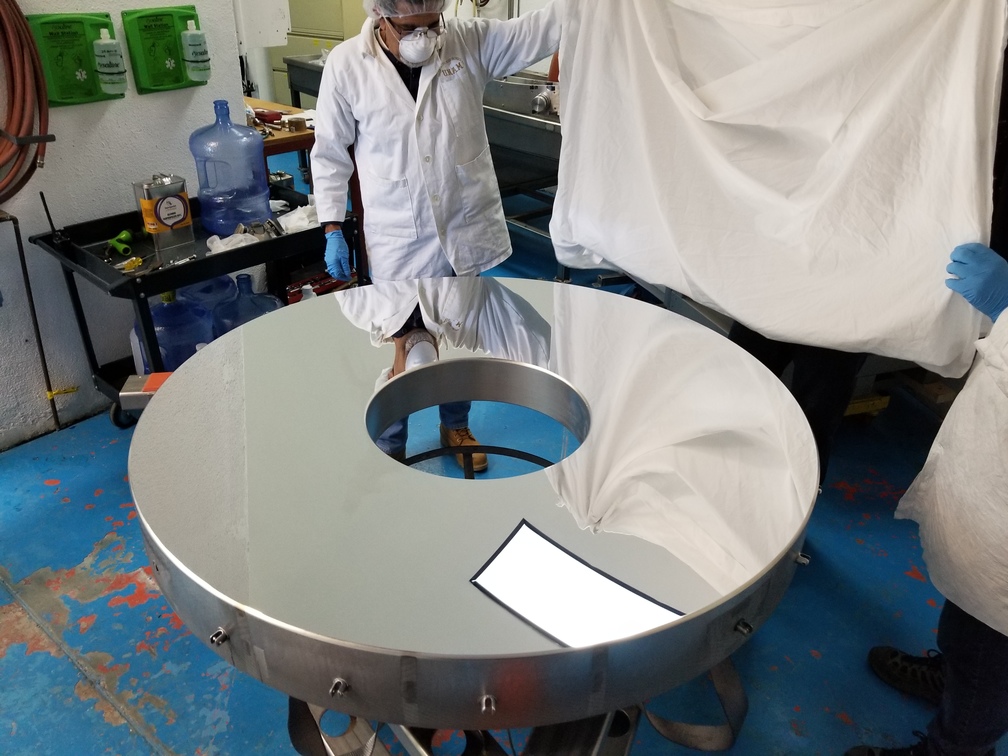

The optics guys finished coating the last primary mirror today. Here is a photo of the second one...

...and here is a photo of the third one.

In the mean time, we finished assembling the primary mirror cells today. Here is the mirror cell from Site #3 after completion.

The other two look the same, so no photos.

We plan to work on installation of mirror doors and trusses tomorrow. We should finish these tasks in the next couple days, after which we will be ready to start installing the primary mirrors into the mirror cells. However, the local crew nee...

2017-09-16

#Telescopes

The local SPM staff got the first primary mirror coated today. They are already getting ready to coat the second one, and we hope to have all three done in the next few days.Here are some photos.Mirror in crate. Still covered with protective later of plastic film.

Lifting mirror out of crate. Piece of glass weighs 900 lbs.

Mirror on cart.

Protective film removed.

Putting on coating fixture to hang mirror in vacuum chamber.

Preparing to lift mirror with coating fixture.

Mirror installed on vacuum chamber cover.

Vacuum chamber.

Optics guys doing a Ronchi test on the mirror.

Read...

2017-09-14

#Telescopes

The construction crew has been working to wrap up the final work on the enclosures. All of the doors have been installed, as well as the exhaust fans. This will help seal up the building, something we found needs to be done as well as we can after Lidia blew through.Here is a photo of the exhaust fan installation at Site #1.

Meanwhile, the electrical crew is back to install a robust grounding system at the three telescope sites. Here is the crew working at Site #1.

2017-09-14

#Enclosures

After finishing the crane work, we spent the past few days mostly finishing up some unexciting, random tasks that needed to be done. We filled in the holes in the observing floors created by trimming the corners off of the lift tables, finished most of the stuff I wanted to do during the last trip (dome home switches, mounting dome control electronics), relocated the lift table hydraulics controls from the trap door in the observing floor to the wall, cleaned all of the trash that the construction crews left on the ground floor of each enclosure, and gave all of the enclosures a thorough vacuu...

2017-09-14

#Telescopes

We completed the crane work at Site #1 early this afternoon. This was the last site to be done, so we are now done with all of the lifting.We plan to spend the afternoon moving two of our primary mirrors out of the 2m building so they can begin coating the other mirror. We expect all mirrors to be coated by the end of next week.Ruben and his crew are back and they have been working to wrap up the enclosure construction. The main things they need to finish are the installations of the observing chamber doors and the exhaust fans. They finished work at Site #2 yesterday, and are working on Site...

2017-09-07

#Telescopes

We installed the pedestal and fork at Site #1 this morning. We got the primary mirror cell/center section/focus housing stack loaded onto the flatbed and up to the site for installation this afternoon, but a thunderstorm came through so we covered everything with a tarp and called it a day. We will get back to work tomorrow morning.Here are a few photos of today's activities.

Getting the pedestal out of the container.

Getting the fork out of the container.

Lifting pedestal.

Lifting the fork.

Pedestal and fork installed.

2017-09-07

#Telescopes

Today we finished all of the crane work at Site #3. We started this morning with the fork and the primary mirror cell/center section/focus housing bundle, and after lunch we lifted everything else: counterweights, Dec drive, electronics rack, trusses, and lots of boxes using a nifty cargo bag that Liliana provided. We will start on Site #1 tomorrow morning.Here are some photos. Not too many today, since most of them look like those from the work at Site #2.

Lifting fork out of container and onto flatbed.

Getting primary mirror cell/center section/focus housing stack out of container.

At Site...

2017-09-06

#Telescopes

Yesterday it was misting most of the day so we did not do any crane work. Instead we continued the work on the lift table modifications. Today, however, was very sunny, so we were able to finish the crane work at Site #2. We also had time to install the pedestal at Site #3, and weather permitting, we expect to finish most, if not all, of the crane work at that site tomorrow.We started the day by lifting the spyder ring and focus housing, after which we separated the center section from the primary mirror cell and lifted and installed it. (The mirror cell stays on the ground floor until t...

2017-09-05

#Telescopes

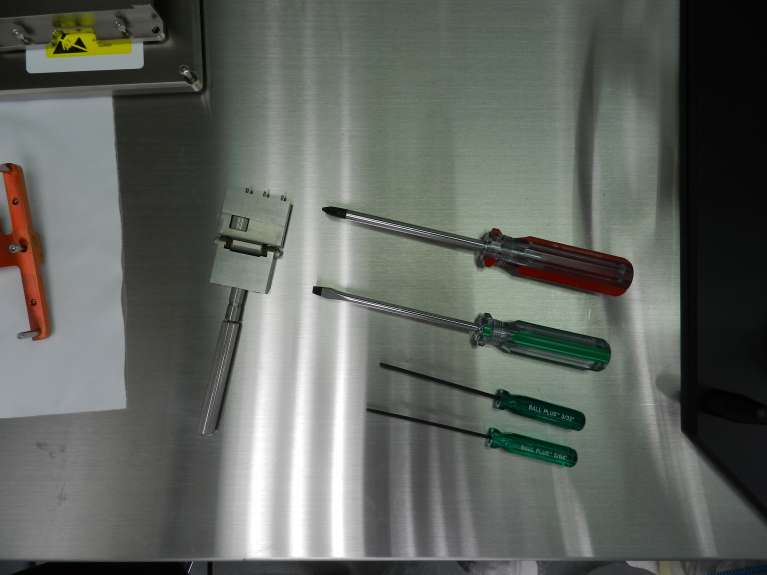

The TAOS II camera mechanical parts have been made and integrated for some time. This is the first attempt to populate the sensors on the cold plate. This is to confirm that the cold plate design is consistent with the CMOS sensor package and also to check the procedure of the sensor installation with the tool we developed. In the process, we used the mechanical sample...

2017-09-05

#Camera

Lidia has arrived at SPM. Winds were too high this morning for any crane work, so we went ahead and fixed a problem we noticed yesterday with the lift table at Site #2, namely that the table wouldn't clear the fork when raised high enough to get the primary mirror cell onto the center section. So we cut off the two corners of the table nearest the telescope, and the problem is now solved.We need to make the same modification to the other two lift tables, but by the time we finished at Site #2, the winds had started to pick up enough that we decided to bug out for the day and head back to the d...

2017-09-02

#Enclosures